How Do Custom Mailer Boxes Make Your Brand Stand Out?

Custom packaging design has become a valuable tool not only for safely shipping products but also for marketing your small business. Custom boxes wholesale can be designed effectively to increase brand awareness and perceived brand value.

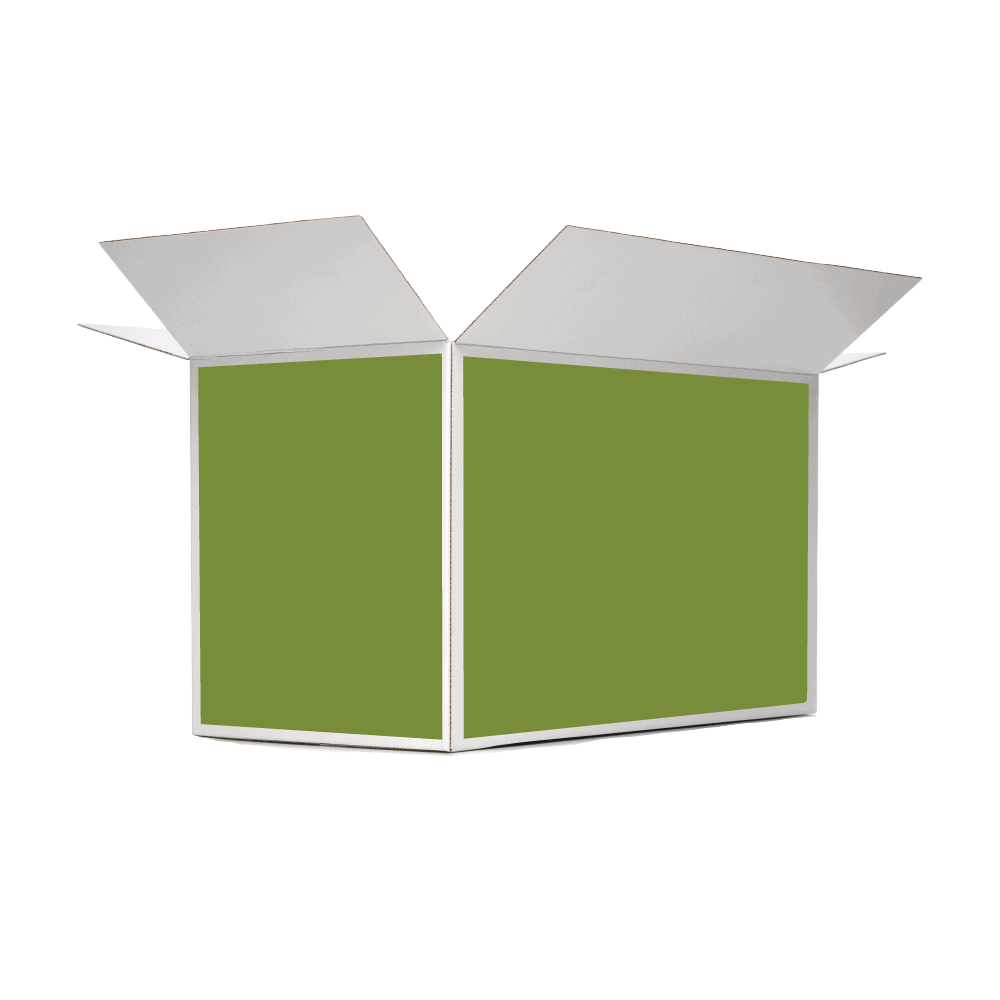

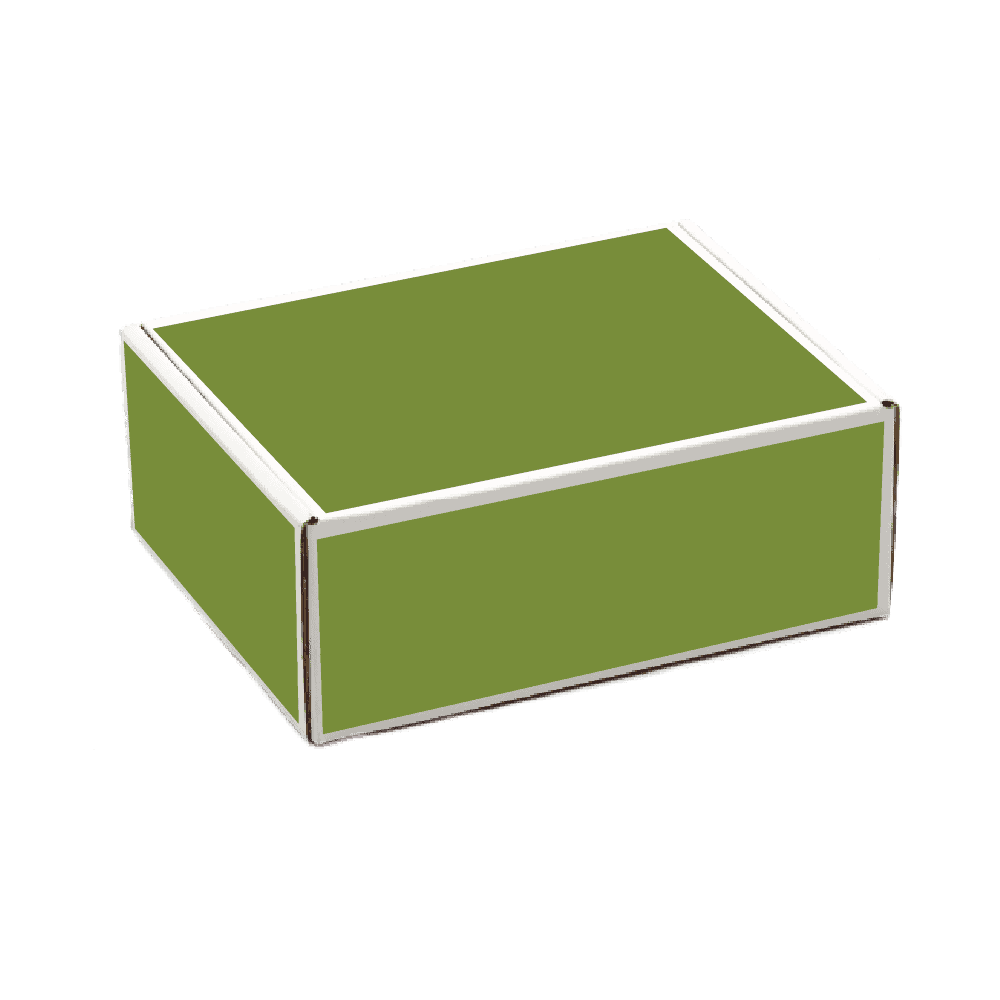

One of the best box types for creating a luxury unboxing experience and increasing your brand value is mailer boxes. With virtually unlimited possibilities thanks to the dual-sided, full-color graphic capabilities, custom mailer boxes are one of the most cost-effective ways to help your brand stand out in the marketplace.

Luxury Custom Mailer Boxes

Custom mailer boxes are the cutting edge of modern marketing. From subscription boxes to e-commerce order fulfillment, mailer boxes offer a premium unboxing experience that wow the customer and secures repeat sales.

The construction of a mailer box is ideal for the contemporary social media unboxing experience, as its self-closing design and dual-sided graphic capabilities make it one of the most premium box types. A custom mailer box also offers additional real estate versus other custom boxes wholesale, so you can add personalized messages, promotional offers, or unique branding on both the inside and outside of the box.

All of these factors work together to create an impressive presentation that improves customer satisfaction and associates your brand with high quality.

Digitally Printed Mailer Boxes

The opportunity for dual-sided graphics is arguably the most significant benefit of utilizing custom mailer boxes. Completely custom packaging design allows you to incorporate your brand name, logo, website, product information and anything else you’d want to include to promote your business.

Digitally printing a custom mailer box familiarizes customers — and every person who sees the box in transit — with your company, logo and branding. The more that people see your company’s branding, the more easily identifiable it will become to them, and the more likely it is that they will use your company in the future when searching for your product or service.

If you want to impress new customers, retain existing ones, and earn more brand recognition along the way, digitally printed custom mailer boxes are an ideal custom packaging solution.

Embellished Mailer Boxes

Small details will help you stand out when it comes to custom packaging design. In the world of custom mailer boxes, this can include shiny, metallic foiling as well as glossy lamination.

There are many possibilities for adding visual interest and texture to your box, helping you set yourself apart from other shipper boxes. If you want eye-catching designs that associate your brand with impressive quality and attention to detail, ask your custom packaging provider about embellishments for your mailer box.

If you’re ready to get started building your custom mailer box, check out Build A Box’s online design tool, where you can quickly and easily make your custom packaging vision a reality. You can also give us a call at (888) 406-1610 or fill out our online contact form to speak with one of our design experts and receive personalized assistance. We’re always happy to answer any of your questions and provide a free quote. No minimum order quantity is required!