Box Styles

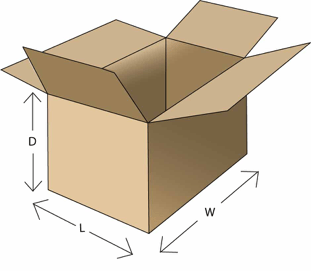

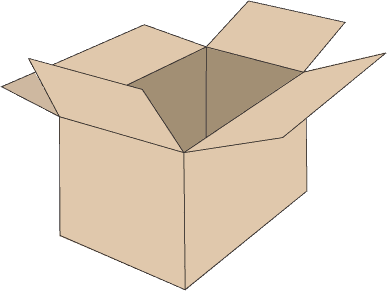

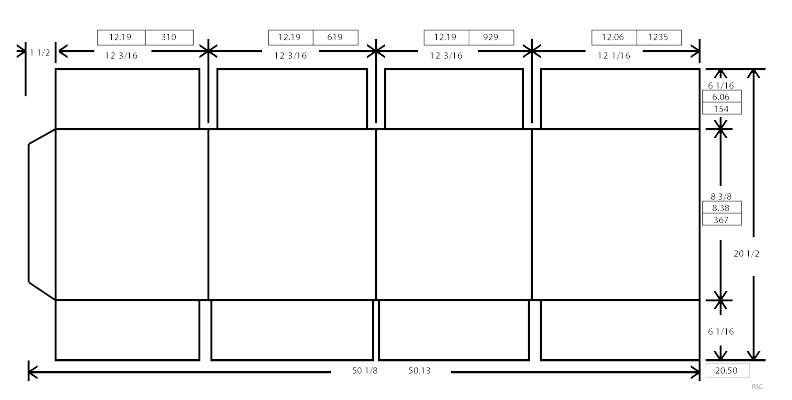

Shipping Box

The shipping box (also known as RSC regular slotted container) is the #1 commonly used box style for shipping and storage. Modifications include stapled sides, taped sides, hand holes, full overlapping flaps, partial overlapping flaps, HSC style where one side of box has no flaps, automatic folding bottom, and snap locking bottom.

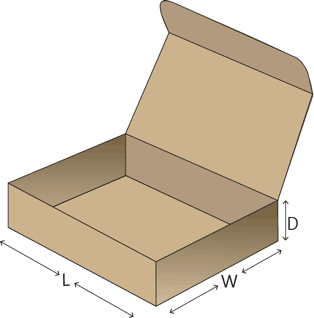

Mailer

Mailer boxes (also know as RETT roll end tuck top) are flat, die cut boxes that are easy to assemble with a simple self-closing design. Commonly used for subscription box delivery.

Modifications include front locking tabs, side dust flaps, catalog lock, and thumbhole for easy opening

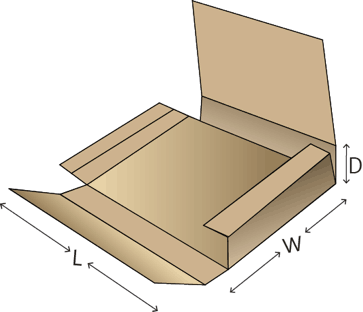

Literature Box

The literature box (also known as OPF one piece folder) is ideal for shipping books, binders, and picture frames. Used often in the printing industry, this style is made to be folded around the product. Modifications include variable depths, self locking tabs, and air cells for protection.

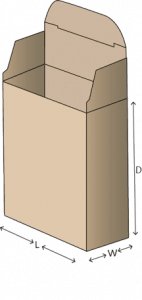

Retail Box

Retail boxes (also known as RTE reverse tuck end) are mostly used for retailing your product as opposed to shipping. It is self-locking and requires no tape or glue to set up for use. Modifications include same-side tuck end, catalog, automatic bottoms, snap lock bottom, and thumb hole for easy opening.

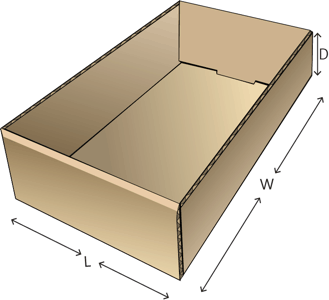

Tray

A tray (also known as DST design style tray) is commonly used for large narrow items like picture frames although they are also used on the top and bottom of pallets. The flaps can be glued, taped or stapled. Modifications include roll end tray, roll side tray, corner cut tray, and telescoping option.

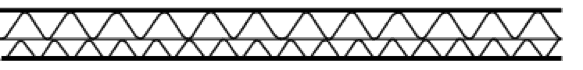

Box Strength

Box strength can be a bit confusing and will vary based on packing applications, however the process can be narrowed down to four simple strengths.

Standard: Standard strength, single-wall box is not recommended to exceed 65 pounds and 75 inches in girth (length + width + depth).

Industry specification: 200lb burst strength or 32 edge crush test

Strong: A more durable single-wall box is not recommended to exceed 90 pounds and 90 inches in girth (length + width + depth)

Industry specification: 275lb burst strength or 44 edge crush test

Standard Double-Wall: Standard double-wall box is not recommended to exceed 65 pounds and 75 inches in girth (length + width + depth).

Industry specification: 200lb d/w burst strength or 42 edge crush test

Heavy Duty Double-Wall: Extra strong double-wall box is not recommended to exceed 120 pounds and 100 inches in girth (length + width + depth).

Industry specification: 350lb d/w burst strength or 51 edge crush test

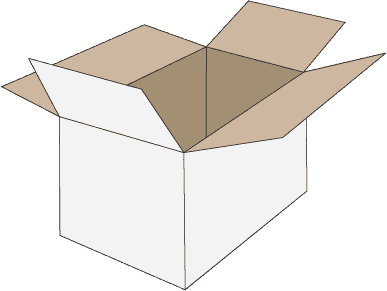

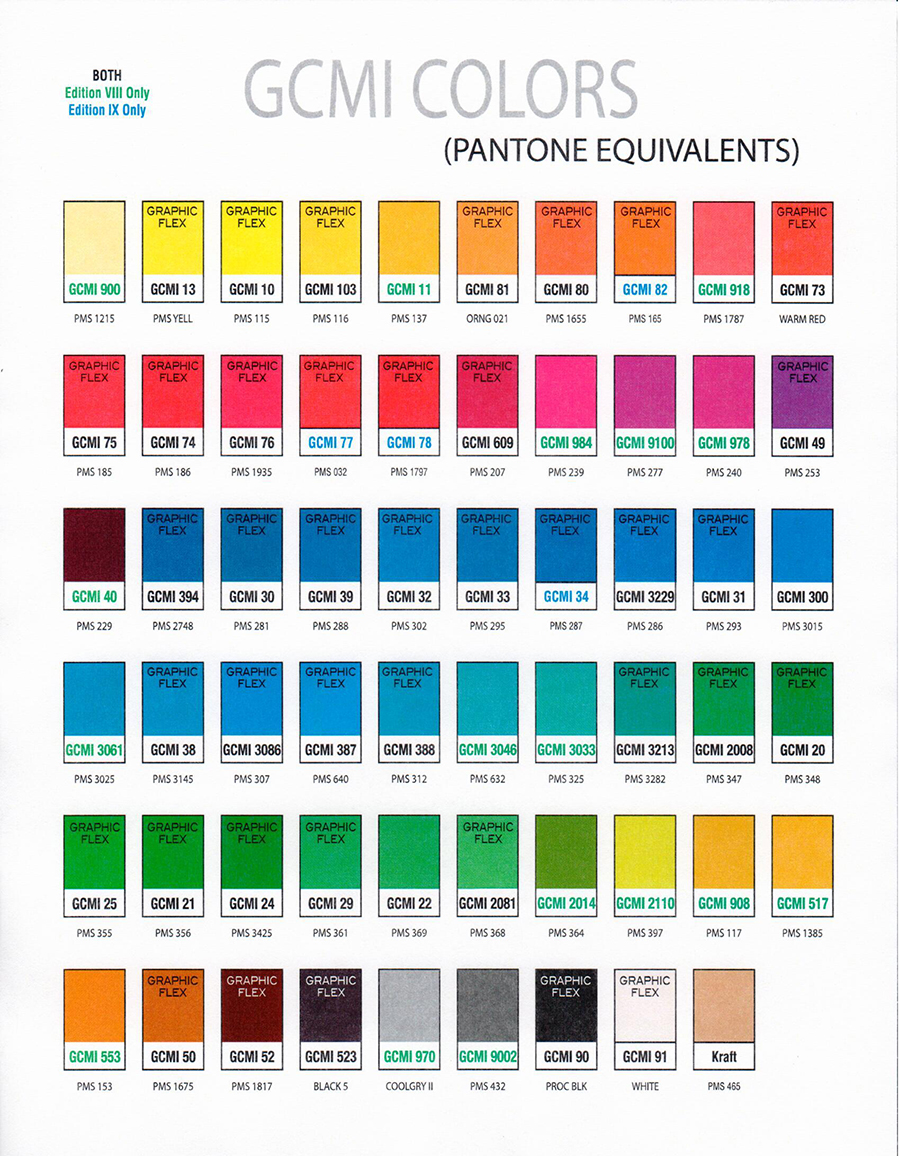

Box Color

Kraft on Kraft is the standard corrugated color (brown) of most plain boxes on the inside and out.

White on Kraft is an off-white color (similar to eggshell white) on the outside and kraft (brown) on the inside. This is the most common white box used in the industry.

Premium White is a bright white on the outside and kraft (brown) on the inside. Premium white boxes is mostly used when printing fine details and is great if your box is going to be for retail and/or sitting on a shelf. It is not recommended for a shipping box.

White on White on the inside and outside can also be made in some cases. However, there are some restrictions/minimums with this type of material. If you’re considering this color, let your design expert know to see if this is right for you.

Colored Boxes can be made with a print process called flood coating. However there are some restrictions/minimums, so check with your design expert to see if colored boxes are right for you.

Cutting Dies (Tooling)

A cutting die is a tool made from heavy plywood, and steel rule, which is bent into the shape of the item to be made and inserted into the plywood: cutting dies are used to make items such as mailers, displays, file boxes, and any item that has a self-locking or self-assembling design. The cutting die is mounted into a die cutting press, which stamps out the item. There are two types of cutting dies: flat and rotary. Flat cutting dies are used for small quantity orders of 1,000 parts or less. Rotary cutting dies are used in high speed presses for projects of 1,000 parts and above. Costs for cutting dies vary greatly, depending on the size, complexity, and type of die required.

Printing Plates

Printing plates are made of highly specialized photopolymer materials and are used to print line art and text directly onto corrugated boxes. This process is known as flexographic printing and a printing plate is required for every image. These plates are mounted onto a sheet of material that matches the item, so the print will be in the proper position each time the item is made. Items that are printed in multiple colors require a separate set of plates for each color. Cost – Traditionally, all printing plates are made and sold through third party trade shops, which sell them to the box manufacturer, who in turn sell them to the box customer. The cost for printing plates varies greatly, depending on the size, complexity and number of colors.

Timing / Lead Time

Standard production time is between 7 to 10 days after the final artwork or sample approval. However, we don’t guarantee any lead times. Check with your design specialist and we may be able to facilitate your needs in a timely manner.

Recycling

The boxes we produce are 100% recyclable and made in the USA. This is a great way to promote your product and show that your company is eco-friendly.