Frequently Asked Questions

Have a question? We can help!

Box and display related…

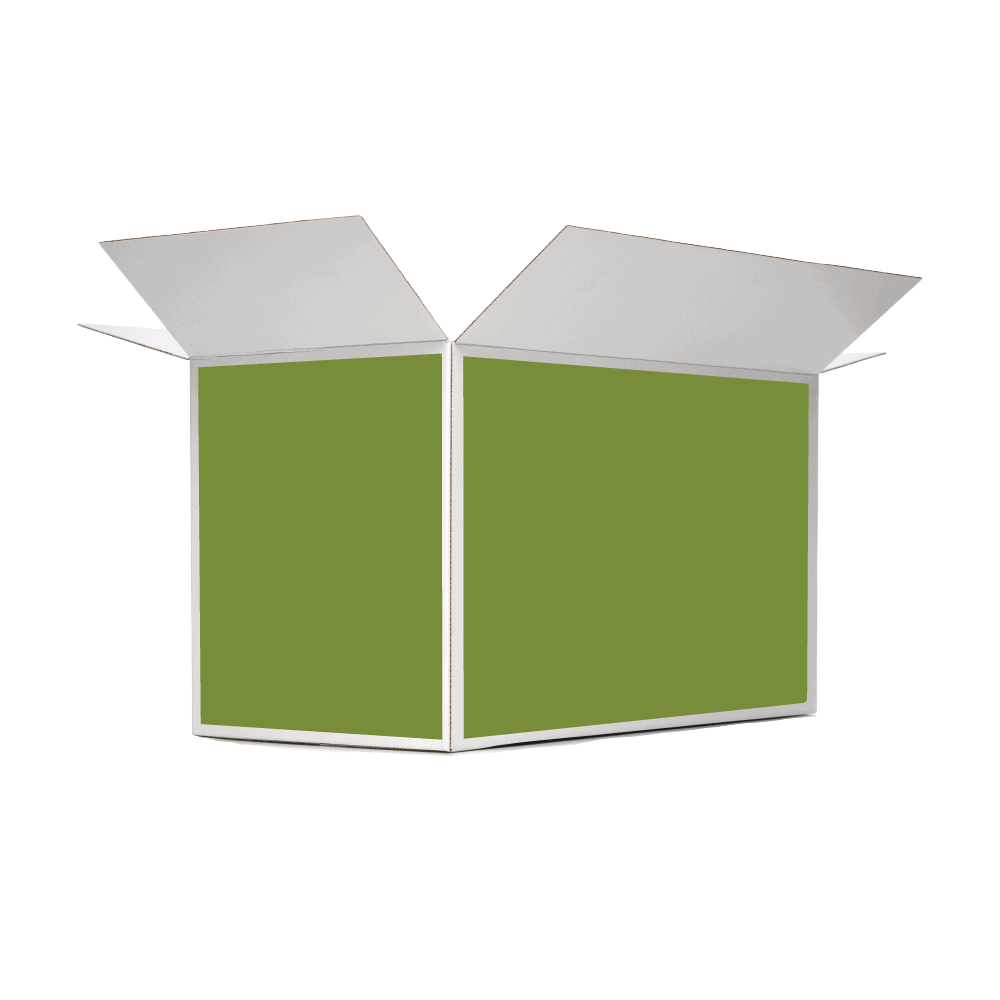

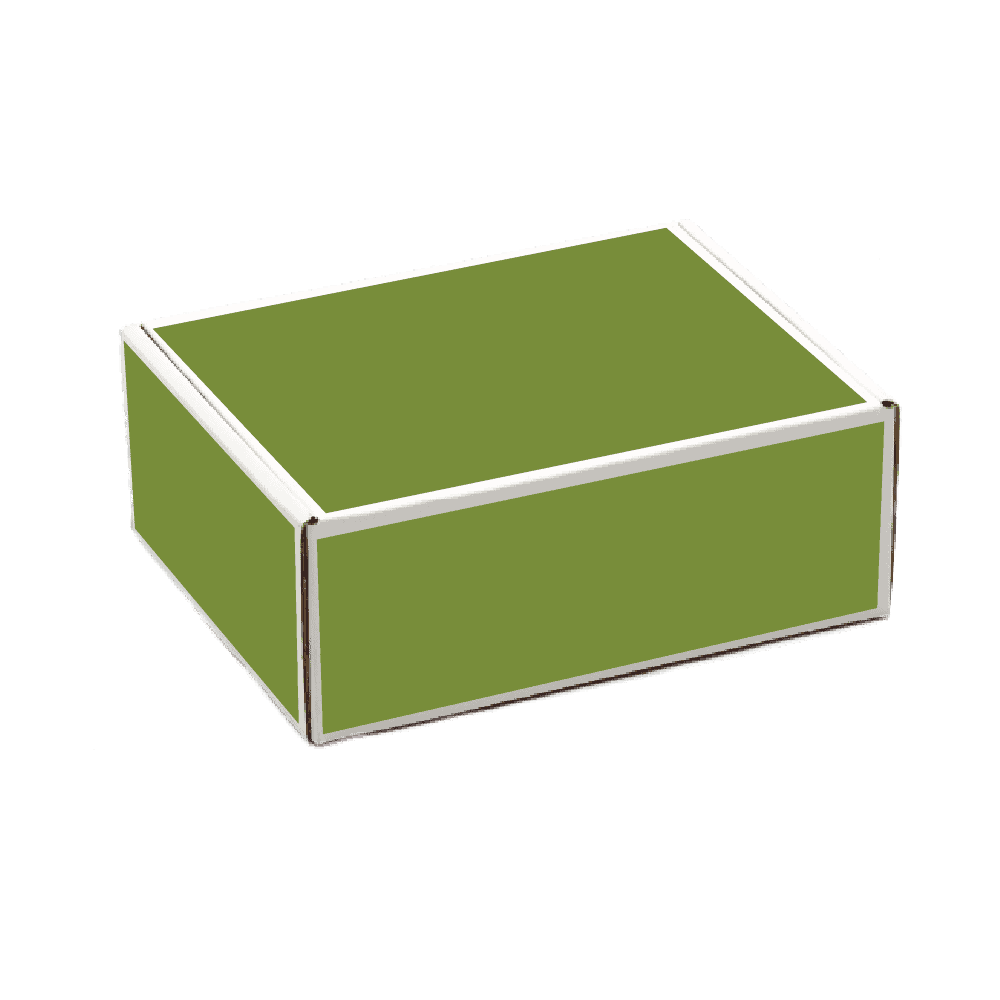

Can you make other types of boxes or displays?

If you can dream it, we can design it! We can make any type of box or display you can think of. Just contact us with your idea and drawings and we will bring it to life.

@buildaboxonline Have an idea? Let’s make it happen!📦 #fypシ #customized #custompackaging #smallbusinesscheck #business #businesspackaging #packagingideas #f ♬ original sound - Nickname

What type of tape should I use on my printed box?

Depending on the finish of your box, some adhesives have trouble sticking to printed surfaces. Storage tape or sealing tape tends to do the best, but any acrylic adhesive that withstands UV light exposure and temperature fluctuations are most recommended.

What thickness of cardboard do you offer?

We offer 3 different thickness strengths: Standard, Strong, and Standard double-wall and Heavy-Duty double wall

Standard board strength comes in:

- C Flute (Industry Standard) About 3/16” Thick

- B Flute (Commonly used for medium sized mailer boxes) About ⅛” thick.

- E Flute (Thinner material commonly used for smaller boxes under 6”) About 3/32” Thick

Based on the size and style that you choose, we make and Industry standard default selection for you in order for your box to close evenly.

Strong board strength comes in:

- C Flute (Industry Standard ) About 3/16” to ¼” Thick

- B Flute (Commonly used for medium sized mailer boxes) About ⅛” thick.

Based on the size and style that you choose, we make and Industry standard default selection for you in order for your box to close evenly.

Standard double-wall and Heavy-Duty double-wall is approx. 5/16” thick or more.

Are your boxes recyclable?

Yes, our boxes are 100% recyclable.

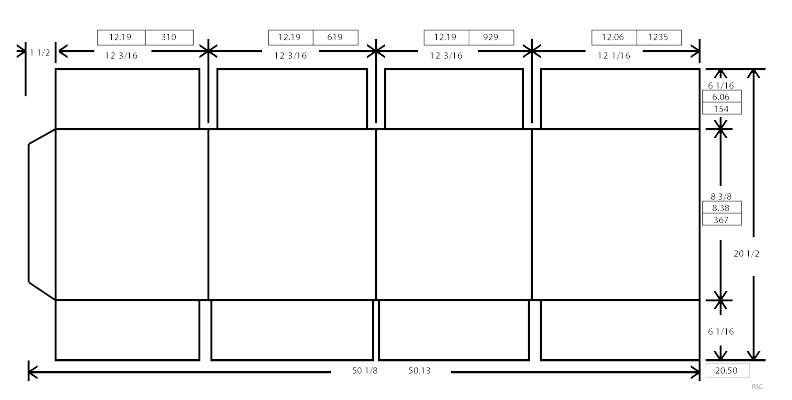

How are dimensions measured?

All dimensions given are based on the inside measurements of the usable space.

Length x Width x Depth

Length = measure left to right

Width = measure front to back

Depth = measure from top to bottom

What type of finishes do you offer?

We can add a stunning visual texture to your box using a high quality four-color process labels, which can be printed with various finishes. We can also use clear laminates over you print that will make you boxes shine. We also do the standard kraft and white paper finish.

What are cutting dies?

Cutting dies are used to make items such as mailers, displays, file boxes and any item that has a self-locking or self-assembling design. Flat cutting dies are used for small quantity orders of 1,000 parts or less, and rotary cutting dies are used in high speed presses for projects of 1,000 parts and above.

Can I print on the inside of box?

Yes! We can print on any side of the box. This is great for mailers, shipping boxes and literature boxes. Let’s chat and get your custom box design built!

Do you make custom inserts?

Yes, we can make custom inserts! However, in most cases we will need your product in hand to size and build a customized insert around.

Artwork related…

Can you do the artwork for me?

Yes and no. We can help with simple design and art placement. However, if you need help with creating logos and designs we suggest you hire a graphic designer.

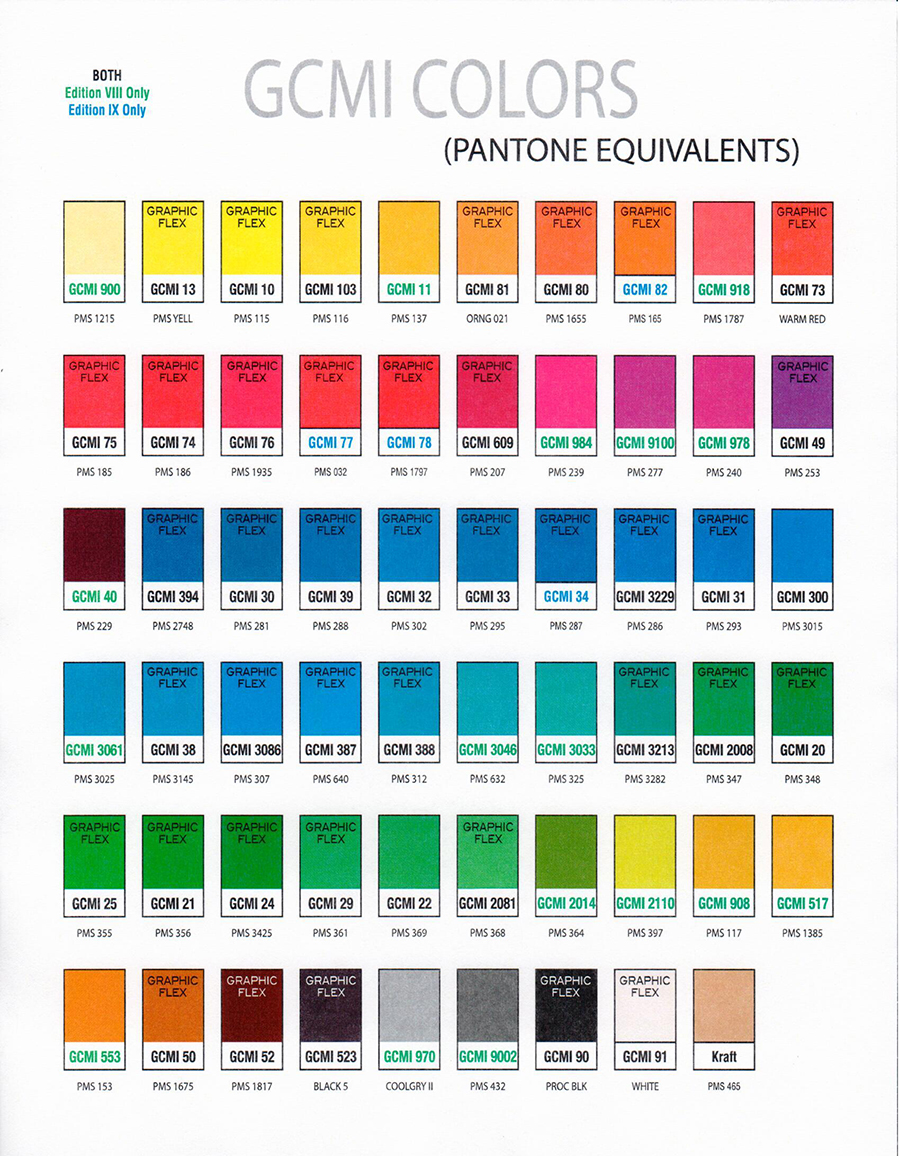

Can you match the colors of my logo?

We can often match PMS colors, however printing on corrugated may be slightly different visually. Please specify the PMS colors you would like to match with your design specialist and we will do the best to match it. A colored swatch on the material you are requesting will be sent out for approval prior to production.

What are print plates?

A print plate is required for every image and are used to print line art and text directly onto corrugated boxes. Plates are mounted onto a sheet of material that matches the item, so the print will be in the proper position each time the item is made. Items that are printed in multiple colors require a separate set of plates for each color. The cost for printing plates will vary, depending on the size, complexity and number of colors.

What format do you need my artwork in?

In order to process your design to print, we will require a “workable” file in return. Any non-photographic content (including graphics and text) are best sent to us as vector-based PDFs or Adobe Illustrator (.AI) files. We will never modify your artwork although we may need to resize your work for a centered panel fit.

Can I print on the inside of box?

Yes! We can print on any side of the box. This is great for mailers, shipping boxes and literature boxes. Let’s chat and get your custom box design built!

Do you offer artwork templates for me to work off of?

Yes, after reaching out on your initial quote, we can provide a mockup artwork template for you to use and create your box, or you can send over the different sections of your box and we can get your art where it needs to go.

Once your project is in production…

When will I receive my order?

Standard production time is between 7 to 10 days after final artwork or sample approval. However, we don’t guarantee any lead times. Check with your design specialist and we may be able to facilitate your needs in a timely manner.

Can I pay for faster lead times?

It’s not often that we can offer this service however check with your design specialist to see if there are some alternatives.

How much is shipping?

We work with a number of reputable shipping carries, it’s difficult to estimate shipping charges until production is complete. All carriers need weight and dimensions, in order to provide an accurate shipping costs. Your corrugated expert will give you an idea of what to expect.

Can you ship to a residence or a storage unit?

Yes, however the costs of shipping to residential will be more expensive than commercial. Work with your design specialist to view the options and find the best fit for you.

Do you ship out of the USA?

Not at this time.

Ordering related…

When will I receive a quote?

Typically, it takes 24 to 48 hours for your design specialist to personally analyze and build your quote. We may even come up with some more efficient options for your particular design.

How do I place an order?

You can start the ordering process by either filling out the related builder to your project or reaching out and start working with a box specialist.

What’s the ordering process?

We require a $99 design fee to get started which applies to your total order if you place an order with us. A non-printed sample of your design will be sent to you for approval for sizing purposes only. Once approved, your order is scheduled for production.

This process can be waived if you’re sure of your sizing or if you’re pressed for time.

There will be a 50% deposit needed with your Purchase Order to get the order started and balance upon delivery.

What form of payments do you accept?

We accept all major credit cards, PayPal and company checks.

Do you have a minimum order?

We do not have a minimum order. However, larger quantities receive better pricing.

What is your return policy?

Because our packaging is fully customized, we cannot offer returns. Our service helps eliminate the problems that may occur when ordering custom packaging. Our design specialists are trained to ask the questions that might be missed. If you have a concern about the product you receive, please contact your corrugated expert, to see if we can solve the issue.

Get started with your custom packaging or display.

Build A Box works diligently to bring your imagination to life through beautifully designed custom boxes. If you’re ready to get started designing your custom box, one of our expert designers will work alongside you through the entire process to help you create the perfect custom box for your business’s needs. If you already have a design in mind, our free online configuration tool allows you to submit your custom creation and receive a free quote with no hassle.